If you have built or renovated a home recently, you have probably heard a lot about energy efficiency. Heat pumps. Better windows. Airtightness. Step Code. Net zero. If even if you haven’t built or renovated a home in recent years, I’m sure these are terms the general public is quite familiar with in BC.

All important things.

But more and more now, we have to ask another question: what about the carbon created before anyone even moves in?

That is where embodied carbon comes in, and it turns out it matters just as much as how efficient the home is to operate.

What is embodied carbon?

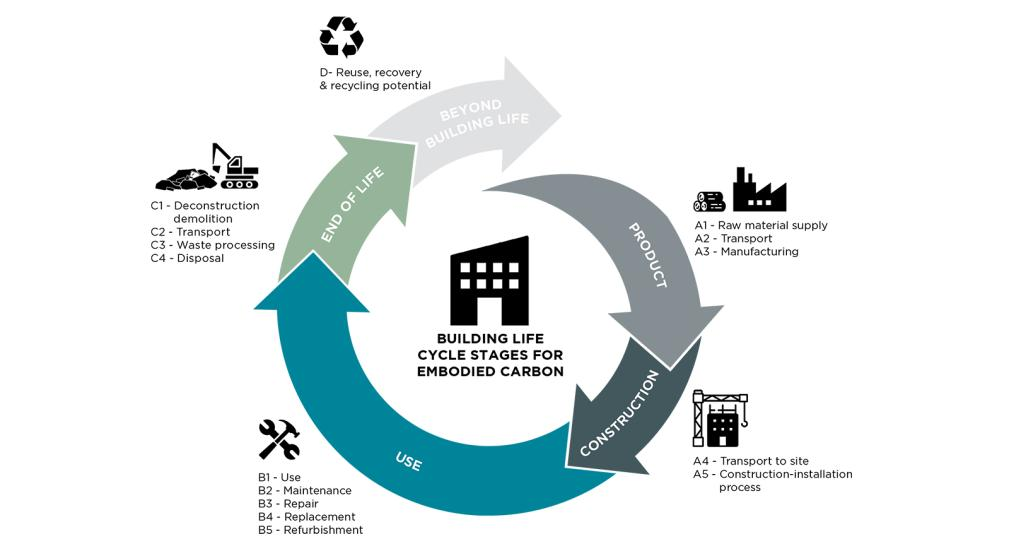

Embodied carbon is the greenhouse gas emissions created by building materials and construction itself. It includes the carbon from extracting raw materials, manufacturing products, transporting them to site, installing them, and eventually replacing or disposing of them.

In contrast, operational carbon is the carbon produced while you live in the home: heating, cooling, hot water, lighting, appliances, and electricity use over time. This has been a big focus for our province in recent years and it’s important, but so is embodied carbon if we want to be looking at a bigger picture when it comes to our housing stock, climate change, healthy homes and resiliency.

The key difference in emissions between operational carbon and embodied carbon is timing.

Operational carbon happens slowly over decades.

Embodied carbon happens mostly upfront, before the house is even finished.

Once a foundation is poured and materials are installed, that carbon is already in the atmosphere. You cannot retrofit it away later.

Here is why embodied carbon matters more than people think…

As homes become more energy efficient and electricity grids continue to decarbonize, operational emissions are dropping. That is a success story, although we are meeting challenges associated with getting there (such is life).

But that also means embodied carbon makes up a larger share of a home’s total climate impact, especially in the first 10 to 20 years. Those early years matter most when it comes to climate change. We know we need to reduce our emissions now as well as into the future.

In even some of the most efficient homes, the upfront embodied carbon can rival decades of operational emissions.

So if the goal is truly low-carbon housing, we cannot focus only on on-going energy use. We also have to look at what we build with and the energy intensity and carbon emissions associated with those products.

Which parts of a house have the biggest embodied carbon impact?

Not all materials are equal. If you want the biggest impact for the least effort, focus on the major contributors first (details on each category below)

- Concrete foundations, slabs, and garages

- Structural systems, including framing and engineered wood

- Insulation choices

- Exterior cladding and major finishes that may be replaced over time

Concrete alone is often one of the largest single sources of embodied carbon in a Construction project. That is why many low-carbon strategies start there.

Let’s take a look at the why on concrete:

Concrete is one of the biggest sources of embodied carbon in a home, mainly because of cement. Making cement releases a lot of carbon dioxide, both from the energy used and from the chemical process itself. Most of that carbon is released before anyone ever moves into the house.

The most effective option here is simply using less concrete. Smarter foundation design, right-sizing footings and slabs, and avoiding overbuilding can reduce carbon and often save money at the same time. Better planning, better outcomes.

When concrete is needed (and here in the Okanagan’s sloping terrain we almost always see basements and therefore concrete), the carbon footprint can be lowered by reducing the amount of cement in the mix. Many Canadian concrete suppliers do this by replacing some cement with industrial by-products like slag or other supplementary materials that perform just as well and often improve durability.

Some concrete plants also use newer technologies that permanently lock small amounts of captured CO₂ into the concrete during mixing. While this does not eliminate cement, it further reduces the overall carbon impact.

Lower-carbon concrete is not about radical materials or risky construction. It is about smarter design, better mixes, and making informed choices early, when they matter most.

How structural choices affect embodied carbon

The structure of a home has a big influence on embodied carbon because it determines how much material is used overall.

Homes with efficient structural layouts typically have lower embodied carbon than designs with long spans, complex geometry, or oversized beams and footings. Using the right amount of material, rather than “more for safety,” is one of the simplest ways to reduce carbon.

In many cases, wood-based structural systems can have a lower embodied carbon footprint than more material-intensive alternatives, especially when they are designed efficiently and sourced responsibly. What matters most is not the label of the system, but whether the structure is optimized and not overbuilt.

Early coordination between the designer, engineer, and builder is key. Once structural decisions are locked in, opportunities to reduce material and carbon are limited.

The most optimal way to reduce embodied carbon via structural choices is from using less material overall and avoiding unnecessary complexity, not from chasing one specific product.

How insulation choices influence embodied carbon

Insulation reduces energy use, but different insulation types come with very different upfront carbon impacts.

Some insulation products are made with high recycled content or bio-based materials, which generally lowers embodied carbon. Others rely on energy-intensive manufacturing and chemical blowing agents, which increases it.

Choosing insulation that matches the needs of the assembly is important. Using the right product in the right place avoids unnecessary layers, reduces waste, and improves durability.

Long-lasting insulation that maintains its performance over time also reduces embodied carbon by avoiding early replacement or upgrades.

The most optimal way to reduce embodied carbon via insulation choices is to choose products that perform consistently over decades, avoiding both carbon and comfort problems down the road.

How exterior cladding and major finishes matter

Exterior cladding and major finishes affect embodied carbon in two ways: how much carbon they carry upfront, and how often they need to be replaced.

Materials that last longer, require less maintenance, and age well tend to have lower lifetime carbon impacts, even if their upfront footprint is slightly higher. Products that need frequent repainting, refinishing, or replacement increase embodied carbon over the life of the home (in addition to the other nuissances).

Simplicity matters. Cladding systems with fewer layers, fewer accessories, and fewer specialty components generally have lower carbon impacts and fewer failure points.

Choosing durable, repairable materials that suit the local climate is one of the most effective long-term carbon reduction strategies available to homeowners.

The most optimal way to reduce embodied carbon in the exterior cladding is to choose one that never needs to be replaced.

- Highly durable cladding designed to last decades with minimal maintenance

- Repairable systems where damaged sections can be replaced without full removal

- Material choices aligned with local climate, moisture exposure, and durability goals

How embodied carbon connects to VOCs and indoor air quality

Embodied carbon and indoor air quality are different issues, but they overlap more than most people realize.

VOCs, or volatile organic compounds, are gases released from certain building products, finishes, and furnishings. Formaldehyde is one of the most well-known examples and is commonly associated with some composite wood products, adhesives, and coatings.

In tighter, more energy-efficient homes, indoor air quality matters more, not less. Pollutants do not leak out the home’s exterior envelope as easily, which means material choices and ventilation design become critical to occupant health.

Many lower embodied carbon material strategies align well with healthier indoor air goals when paired with low-emitting products. Fewer synthetic binders, lower solvent use, and more durable assemblies will results in fewer VOC emissions over time into the air you breathe day in and day out.

Below is a list of some Canadian building products with a focus on lower embodied carbon and healthier interiors:

Lower embodied carbon does not have to mean experimental or hard to obtain. Many options are already on the market in Canada.

Lower carbon concrete options:

CarbonCure-enabled concrete

CarbonCure is a Canadian company whose technology is used by many concrete producers across the country. It injects captured CO2 into concrete during mixing, reducing the carbon footprint of the mix while maintaining performance. Always request the producer-specific mix design and environmental product declaration.

ECOPact low-carbon concrete

ECOPact is a branded low-carbon concrete line available through select Canadian producers. Carbon reductions vary by region and mix, so it is important to compare against a local baseline rather than generic claims.

CarbiCrete concrete products

CarbiCrete is a Canadian technology producing cement-free concrete masonry products using industrial by-products and carbon mineralization. Availability depends on region and application, but it shows where the industry is heading.

Structural wood and mass timber products

Mass timber and engineered wood can reduce embodied carbon compared to more carbon-intensive structural systems, depending on what they replace and how efficiently they are designed.

Kalesnikoff CLT (British Columbia)

Kalesnikoff manufactures cross-laminated timber and publishes environmental product declarations for its products. Located in Castlegar, BC.

Nordic Structures (Quebec)

Nordic produces CLT and glulam products with published environmental documentation.

From an indoor air quality perspective, structural wood itself is typically not a major VOC source. Attention should instead be paid to coatings, sealants, and interior finishes used alongside it.

Lower embodied carbon insulation options

Cellulose insulation

Cellulose insulation is made primarily from recycled paper fiber and is widely used in Canada. It generally has lower embodied carbon than many foam-based insulations and is commonly recognized for its low VOC emissions. This comes from Canadian companies like: Igloo Cellulose Inc., Climatizer Insulation, Sopra-Cellulose, Therm-o-Comfort, Prairie Fibre Insulation Company. A number of these products are available from Home Depot.

Wood fibre insulation

Products such as SONOclimat ECO4 are manufactured in Canada from recycled wood fibre. These products offer a bio-based alternative for exterior sheathing and insulation layers.

Wool insulation

Sheep’s wool insulation products are available in Canada and are bio-based. While not suitable for every application, they are often chosen for their low chemical emissions and moisture-handling properties. These include products like: Havelock Wool, EcoWool Canada, while stone wool insulation alternatives are great too – products like: Rockwool (already highly used in the Okanagan and produced in Grand Forks), and Soprarock

Cabinetry and millwork with lower VOC emissions

Cabinet boxes and millwork are one of the most common hidden sources of formaldehyde in homes.

Canadian manufacturers such as Tafisa offer decorative panels and substrates that meet ultra-low emitting formaldehyde standards. When specifying cabinetry, requesting ULEF or no-added-formaldehyde materials can significantly improve indoor air quality.

Low VOC paints and finishes

Paint and coatings may not dominate embodied carbon calculations, but they have an outsized impact on how a home feels when you move in.

Canadian manufacturers like Cloverdale Paint (BC-based) offer low VOC and near-zero VOC product lines. In airtight homes, these choices can make a noticeable difference in comfort and air quality during and after construction. There are many other paint companies that supply low or near-zero VOC product lines, and the most noteable Canadian ones are:

| Company | Key Low/No-VOC Line | Focus Area |

|---|---|---|

| Cloverdale | Ecologic® | High-performance, Walls |

| BeautiTone (Home Hardware) | Designer Series | Residential, Versatile |

| Benjamin Moore (manufactured in Canada but American owned company) | Natura / Eco Spec | Premium, Low odour |

How to apply this on a real residential project

For homeowners

Ask early if embodied carbon is being considered at all. Even simple decisions like lower carbon concrete or cellulose insulation can make a meaningful difference. Pair low-emitting materials with a well-designed ventilation system to maintain good indoor air quality.

For builders and designers

Start with the structure and foundation. That is where the biggest embodied carbon reductions usually live. Request environmental product declarations when possible and avoid material substitutions that compromise durability. A durable building is a low-carbon building.

When it comes to the energy intensity of a home, you can reduce your bills over time on the operational side of things, but you only get one chance to choose what you build with.

Both operational and embodied carbon matter and the most successful projects address both from the start.